Value creation from waste? – 3,000 tonnes of unused potential

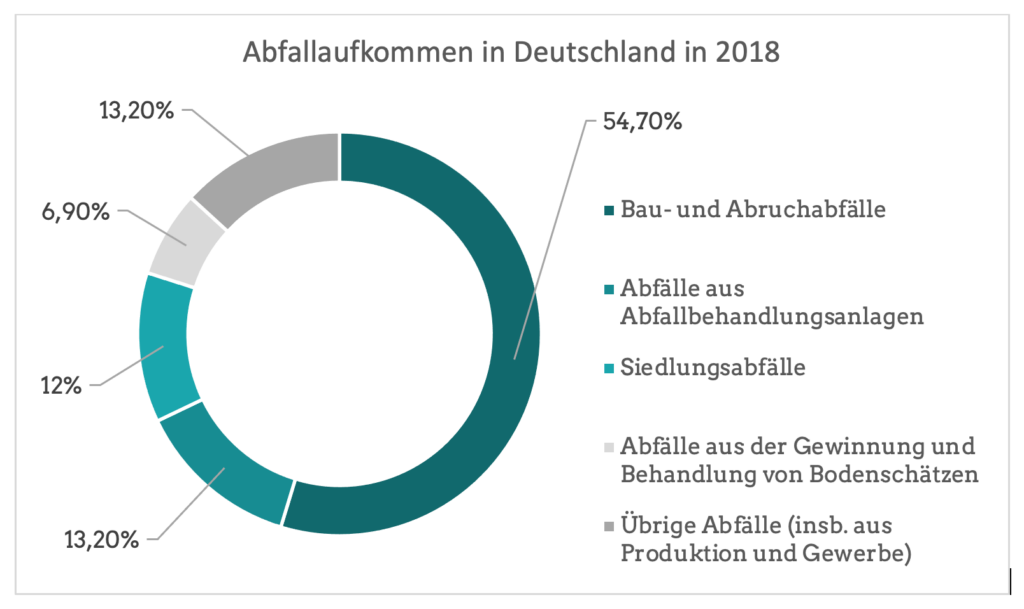

According to the Federal Statistical Office of Germany, 417 million tonnes of waste were generated in 2018. Of this, 338.5 million tonnes were recycled for materials or energy. This corresponds to a recovery rate of 81.1 %. It has thus risen continuously since 2006 (74.3 %). The recycling rate, on the other hand – that is, the proportion of waste with material recovery as a percentage of all waste generated – remained almost unchanged at around 70 % (2006: 69.4 %, 2018: 69.6 %) [1].

Part of this waste is fibrous waste from various industries. Fibre-reinforced plastics are mainly used in aviation, automotive, wind energy production, the sports equipment industry and, for some years now, also in construction. Depending on the area of application, different fibre materials such as carbon, glass, basalt or basalt fibres are used [2], [3].

In the coming years, waste containing glass fibres will increasingly occur as wind turbines that have reached the end of their operational cycle are dismantled. Wind turbine rotor blades are largely made of glass-fibre reinforced plastic. The amount of waste generated is estimated at several thousand tonnes [4], [5]. Possible scenarios for dealing with decommissioned wind turbines are described, for example in the research paper [6].

Large quantities of production waste are already being generated in the manufacture of carbon-fibre reinforced products in the Federal Republic of Germany. According to the German Environment Agency (2020), waste containing carbon fibres amounted to 870 tonnes and waste containing carbon-fibre reinforced plastics to around 3,000 tonnes in 2017. The increasing global demand for fibres and products made from carbon consequently indicates a potential for value creation through the reprocessing and reuse of recovered fibres [8].

Speaking of waste: waste is generated not only at the end of the respective use of the components, but also during the original production. Two types of waste occur during the processing of fibre-reinforced plastic composites. So-called “dry” waste, where the fibres have not yet been processed with plastic as a composite component, and waste from fibre composites, where the fibre first has to be separated from the matrix component for recycling.

As of 2020-12-21

List of references

[1] Statistisches Bundesamt (2020). Abfallwirtschaft. URL: https://www.destatis.de/DE/Themen/Gesellschaft-Umwelt/Umwelt/Abfallwirtschaft/_inhalt.html

[2] LAGA (2019). Abschlussbericht zur Entsorgung faserhaltiger Abfälle. URL: https://www.laga-online.de/documents/bericht-laga-ausschuss-entsorgung-faserhaltige-abfaelle_juli-2019_1574075541.pdf

[3] Schürmann, H. (2007). Konstruieren mit Faser-Kunststoff-Verbunden: mit 39 Tabellen. https://doi.org/10.1007/978-3-540-72190-1.

[4] Beauson, J., & Brøndsted, P. (2016). Wind Turbine Blades: An End of Life Perspective. In Ostachowicz W., McGugan M., Schröder-Hinrichs J.-U., & Luczak M. (Eds.), MARE-WINT, 421-432. https://doi.org/10.1007/978-3-319-39095-6_2.

[5] Jensen, J. P. (2019). Evaluating the environmental impacts of recycling wind turbines. In Wind Energy, 22(2), 316-326. https://doi.org/10.1002/we.2287

[6] Sakellariou, N. (2018). Current and potential decommissioning scenarios for end-of-life composite wind blades. In Energy Syst, 9(4), 981-1023. https://doi.org/10.1007/s12667-017-0245-9

[7] Meunier, C. (2020). Faserverbundwerkstoffe: Zukunftsmaterial mit offener Entsorgung. Umweltbundesamt. URL: https://www.umweltbundesamt.de/faserverbundwerkstoffe-zukunftsmaterial-offener

[8] Composites-Marktbericht 2019. URL: https://composites-united.com/media/3989/ger_ccev_marktbericht_2019_kurzversion.pdf

About the partnership

Be part of the alliance and join us in facing the challenges with regard to the no longer avoidable handling of fiber composites. Let us together lead the region “Elbe Valley Saxony” into an economically resilient future.